productivity computation for ball mill

Comparative Study on Improving the Ball Mill Process

2021年2月19日 Optimization results confirmed that the balls to powder weight ratio were the most influential process parameter. The optimum process parameters setting concluded that balls to powder weight ratio are 20:1, the optimum ball mill working capacity is 2 L

اObtener precio

Development of operation strategies for variable speed ball mills

Abstract. Mineral processing productivity relates to a range of operating parameters, including production rate, product grind size, and energy efficiency. Variations in ore

اObtener precio

Determining Optimum Productivity of a Ball Drum Mill

2021年2月8日 Ball drum mills (BDM) are one of the main types of coal-grinding equipment in Russia. A significant drawback of BDM is high power consumption (a significan

اObtener precio

Determining Optimum Productivity of a Ball Drum Mill

2021年2月1日 The method for determining the ball load and the grinding capacity from the power consumed by the ball-tube mill under operating and emptying conditions is

اObtener precio

Ball Mill - an overview ScienceDirect Topics

Generally, filling the mill by balls must not exceed 30–35% of its volume. Productivity of ball mills depends on drum diameter and the relation of drum diameter and length.

اObtener precio

MODULE #5: FUNCTIONAL PERFOMANCE OF BALL MILLING

If a ball mill contained only coarse particles, then 100% of the mill grinding volume and power draw would be applied to the grinding of coarse particles. In reality, the mill

اObtener precio

(PDF) Performance optimization of an industrial ball mill

2017年1月1日 In this investigation, we optimize the grinding circuit of a typical chromite beneficiation plant in India. The run-of-mine ore is reduced to a particle size of less than 1 mm in the comminution ...

اObtener precio

Ball Mill Parameter Selection Calculation - JXSC

2019年8月30日 It is difficult to theoretically determine the productivity of the mill. The grinding mill’s production capacity is generally calculated based on the newly generated

اObtener precio

Ball Mill Design/Power Calculation - 911 Metallurgist

2015年6月19日 The basic parameters used in ball mill design (power calculations), rod mill or any tumbling mill sizing are; material to be ground, characteristics, Bond Work Index, bulk density, specific density, desired

اObtener precio

productivity computation for ball mill

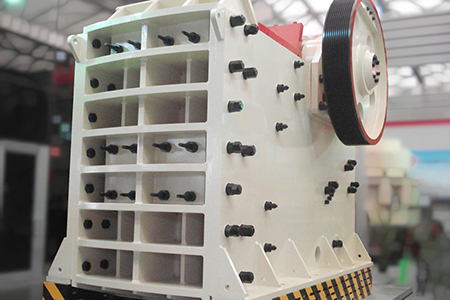

Productivity Computation For Ball Mill. Processing capacity:153-459t/h Feeding size:≤23mm Appliable Materials: quartz,cement,silicate,new-type building material,ore

اObtener precioMas noticias

- trituradora de mandíbulas usadas en perú

- molino flor celular

- especificaciones tecnicas del molino de bolas de molienda

- mineria el cenit de la maquina trituradora de

- fabrica de cola

- Trituradora Minera Del Oeste De Australia

- Proveedores de Molinos de Energia de Fluidos En méxico

- molinillo de maíz molinillo de maíz

- Arena chancador de roca

- gold ore crushing machine small scale

- dise1o de molino para plastico

- venta de bola de molienda planta de procesamiento de molino

- consentimiento de establecimiento de trituradora de piedra en orissa

- maquinaria de minería huwood

- c3mo moler en un polvo de piedras

- tanque de lixiviacion de lixiviacion y adsorcion

- molino de pisones stamp mill

- molino horizonta pde piedra para moler cacao

- calcite grinding ball mill performance grinding mill china

- mineral de cuarzo molinos en Bolivia

- equipos de minerada de oro en suda1n precios trituradora para la venta

- trituradora de cantera para la venta precio en letonia

- molinos de quebra el maiz pato

- extracción y procesamiento de cobre

- maquina de bolas molino filipinas

- trituradoras de cono incluyen

- shandong molinos de bolas en quito

- molino de moler ma 237 z

- verificado calidad de mineral de plomo de equipo de procesamiento de equipos de china

- para laminados lijadora